The manufacturing technology of PHC pile

In order to manufacture high quality PHC pile constantly, we take the following technical measures through a lot of tests for manufacturing technology:

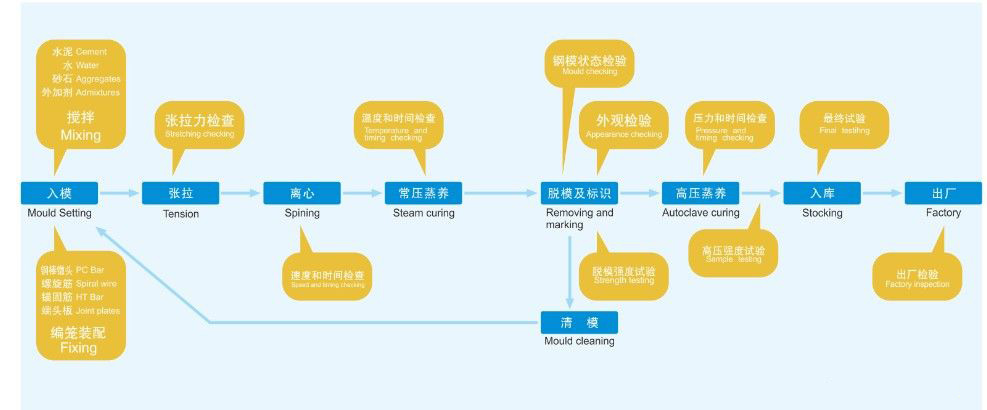

Fig. 1 Brief producing process chart of PHC pile

We give the priority to the use of portland cement with 525 mark. The water/cement ratio is controlled strickly to be no more than 0.3 by adding high-water reducing agent and additive.

SEC technology is used to strengthen the interfacial strength and property.

The relative tolerance of cut length of prestressing wire shall not be more than L/5000 and pretensioning test after button headed has to be carried out.

The steel cage forming machine made in China is used for weaving the steel cage automatically so as to increase the globality of steel cage.

The four stages centrifugal casting system is used, the compactness of concrete can be increased, the outer segregation and w/c ratio reducing can be carried out by the high speed centrifugal casting (centrifugal acceleration is more than 35g). therefore the strength and durability of concrete can be increased.

by using the low temperature steam curing technology, the damaging effect of steam curing to concrete structures can be reduced and is favourable to increase the concrete strength on the twice autoclaving curing. the use of twice curing method makes concrete strength grade of pile to be more than C80 steadily.