A centrifugal process for producing concrete piles in China

[0001] The present invention relates to a manufacturing process of a centrifugal concrete pile. Background technique:

[0002] China since the early 1980s began the introduction, development and production of prestressed concrete pipe pile. 90 years of the last century, pile in the rapid development of our country, from the north coast of Guangdong, at the same time, with the implementation of western development strategy, technology pile all the way west. At present, China's output of concrete pipe pile not only among the world's first column, the type is among the highest in the world. In recent years, prestressed concrete square pile as a new type of pile appeared in the market. Prestressed concrete piles with the same party prestressed concrete pipe pile centrifugal molding process, having the outward appearance of the structure of the circle, easily fixed transportation, banding; when using the probability of pile construction hold pieces holding pressure Pipe accidents than Save small; pile caps dimensions are more reduced, thereby reducing the project cost. Requirements of sustainable development in line with the development of precast concrete piles of building materials, factory prefabricated concrete piles in favor of automation, large-scale, efficient production, not only easy to control and quality assurance, it is also able to reduce the use of non-renewable concrete sand, stone waste of resources, after transport to the construction site, on-site construction is fast, clean construction. Due to the high pile capacity prestressed concrete pipe piles and prestressed concrete square pile (prestressed concrete pipe piles with up to C80 strength grade concrete), more and more sink holes pile, on-site production of reinforced concrete square piles, drilled steel pipe pile and pile hole precast concrete piles are substituted. Prestressed reinforced prestressed concrete pipe pile with a tensile strength of not less than 1420 MPa, non-proportional extension strength of not less than 1280MPa. Pile steel bar for prestressed concrete, because of its high strength, high prestressing of the lower reinforcement of concrete pipe pile that can meet the design requirements of bending properties, which only requires reinforcement ratio of not less than 0.4% i.e. can. In order to pursue the production of high-strength concrete, reducing the production cost is low, prestressing steel are often super-tension phenomenon, the compressive strength of concrete pile is easier to meet product standards. Prestressed concrete square pile design there is also a low ratio of reinforcement problem, there is also the production of ultra-tensioned prestressed phenomenon. The concrete is a typical brittle material, a high modulus of elasticity, compressive and tensile correspondence to the radio. Reinforcement ratio and ultra-low tension, resulting in significantly increased brittleness pile, transportation, during pile driving Pile chance of brittle fracture is significantly improved. In addition, with the recent in-depth study of prestressed concrete pipe piles and piles of prestressed concrete square, their level of capacity, particularly horizontal bearing capacity of prestressed concrete pipe piles have different views. Therefore, national and some provincial standards or regulations made Atlas, the scope of prestressed concrete pipe pile non-seismic area and the seismic intensity of 6 degrees, 7 degrees in the area, if used in the seismic intensity of 8 degrees in the region, the to be subject to checking; or should not be used in areas where seismic intensity of 8 degrees.

[0003] In the area of 8 degrees with a seismic or seismic intensity requirements, pile narrow range of choice, solid square piles or precast piles. Prefabricated solid square piles has its own characteristics. Grade of concrete is C50, 350 X 350mm square pile bearing capacity corresponds to the Φ 300PHC Pile, 400 X 400mm square pile corresponds Φ350ΡΗ (: Pipe, 450X450mm square pile corresponds Φ400ΡΗ (:. In addition to single Pipe pile vertical bearing capacity comparable, the prefabricated solid square pile also have high levels of bearing capacity, suitable for use in areas of high seismic fortification intensity. However, there is a solid square precast piles due to its self-important, mainly the production site prefabricated, natural curing process, low production efficiency, long production cycle, occupies a large space; natural curing process significantly affected by the weather, to affect the hydration process of the cementitious materials, cement strength development process and microstructural features Pile Yes. underground construction, concealed, many unpredictable factors, quality control difficulties SUMMARY:

[0004] The present invention to solve the brittleness of prestressed concrete piles, pile foundation level insufficient bearing capacity problems, and the current low productivity concrete square piles and piles difficult to control quality, guaranteed issue, from steel reinforcement ratio and selection , and other aspects of the production process starting, and changing the selection principle reinforcement steel prior prestressed concrete pipe pile side and prestressed concrete piles, without reducing the vertical bearing capacity, produce centrifugal meet seismic requirements concrete piles.

[0005] aspect of the present invention is:

[0006] The manufacturing process of a centrifugal concrete piles, characterized in that: the process of:

[0007] (1) Preparation of rebar cage reinforcement uniformly spaced along the cross-sectional average number is not less than 6; stirrups include cyclic and spiral pile ends within the range of 2000mm stirrups encrypted area, this range within the annular spacing of stirrups stirrups and spiral pitch is not larger than 45mm, and the rest of the annular spiral stirrups stirrup spacing pitch no greater than 80mm, and will make a good reinforcement cage placed on the lower mold;

[0008] (2) an end plate assembly, at a position corresponding to the end plate and the reinforcement have the same number of reinforcement opening counterbore, the end plate is positioned inside the prepared hole; penetration counterbore after reinforcement with welded end plates;

[0009] (3) cement, sand, stone, mineral admixtures and superplasticizer according to a bulk density, water-cement ratio of 0.25~0.35, sand ratio 0.25~0.38, the total gelling materials with 0.16~0.21 ratio, mineral additives content controlled within 30% of the total cementitious material, depending on the superplasticizer water reducing rate, the dosage of 0.6~3.0% each metered raw materials, after mixing, fabric, molded together concrete pile;

[0010] (4) at one end of the concrete pile strands tensioning machine employed, in accordance with the production process prestressing reinforcement, so that the effective compressive prestress in concrete 3. 0~5 ON / mm2.;

[0011] (5) After the stretch step, the mold is placed on the belt Φ300-Φ600/15Μ frequency concrete pile machines' roller, centrifugal molding, into low-speed-high speed-high speed four stages: low 200~300r/min to run 2~3min; speed 500~600r/min operation 1~2min; high-speed800~1000r/min running 1.5~3min; high speed 1100~1400r/min running 5~10min;

[0012] (6) lifting the mold with the concrete pile to steam curing tank, allowed to stand 2~4h, then through the steam curing, heated to 80~85°C within 3h, 4 ~ kept at a temperature of 80~85°C 6h, 3h and then cooled to room temperature; secondary autoclave curing in the autoclave was heated to 175~185°C in 3~4h, raised to 0.8~1.2MPa, April to pressure after maintaining the temperature. he, 2~3h pool the pressure was reduced to atmospheric pressure in the autoclave, the autoclave when the temperature is below 100°C, open pile transport vessel;

[0013] (7) with the pile lifting the mold to release zone, stripping, passing routine testing, to yard crane.

[0014] Step II reinforcement selection stage (1), stage III, IV and drawing hot rolled steel ribbed steel, or a mixture of two steels.

[0015] Step stirrup (1) binding using the welding reinforcement coupled manner.

[0016] Step O) is a closed end plate is annular end plate or solid end plate.

[0017] The closed loop shape of the end plate is circular, the outer circular shape.

[0018] Step mineral admixture (3) comprises a fly ash, slag, quartz sand powder, silica fume having latent hydraulic properties, or as having pozzolanic properties, while having latent hydraulic or pozzolanic properties and a variety of silicon mass, silicon aluminum material.

[0019] Advantageous effects of the invention:

[0020] The manufacturing process of the concrete pile of the present invention, the design value of bending capacity of the pile can seriously increase more than 12%, tensile tension bearing capacity design value may be increased by 10%. Also effective to reduce or avoid brittle fracture problems of the pile while the pile horizontal bearing the same condition is improved.

BRIEF DESCRIPTION OF 4:

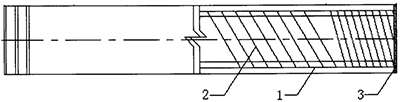

[0021] FIG. 1 is a longitudinal cross-sectional view of the present invention;

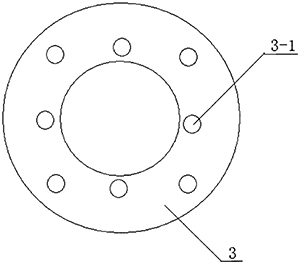

[0022] FIG. 2 is a schematic end view of the principal embodiment of the present invention;

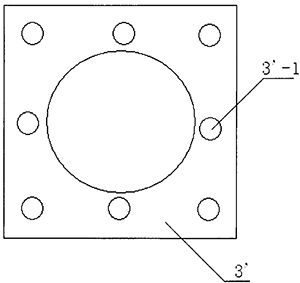

[0023] FIG. 3 is a schematic view according to a second end of the principal embodiment of the present invention;

[0024] FIG. 4 is a process flow diagram of the present invention.

Detailed ways:

[0025] The following Examples and accompanying drawings further illustrate the present invention:

[0026] As shown in FIG 1: Concrete piles square steel reinforcement assembly comprises a spiral stirrup 2, the end plate 3 and a skirt. End regions of stirrups encrypted area, a length in the range of 2000mm; in this region, not more than 45mm pitch spiral stirrups; pile within the other ranges, the pitch of the spiral stirrups of no greater than 80mm.

[0027] Figure 2: Example of the present embodiment is a square annular concrete pile, said end plate 3 is a ring structure, which is provided with a counterbore surface 3-1, 3-1 and the number of reinforcement counterbore 1 same, inside the blind hole in the end plate 3; 1 after the penetration reinforcement counterbore, the end plate 3 are welded; polished flat outer surface of the end plate 3 above the seam, if necessary.

[0028] Figure 3: Example of the present embodiment is the circle outward Concrete Pipe 3' of the end plate 3' is a square structure which is provided with a counterbore surface 3'-1 counterbore 3'-a reinforcement same as the number 1, at the bottom outlet end plate 3 'inside; 3 counterbore penetration reinforcement 1' by -1, the end plate 3 'welding; polished flat end plates 3, if necessary,' above the outer surface of the weld.

[0029] Example a:

[0030] As shown in FIG. 1, 2 and 4, the centrifugal concrete pipe pile manufacturing process is as follows:

[0031] (1) Preparation of reinforcement cage, the reinforcement cross-section along an average uniform distribution, the number of not less than 6; stirrups 2 and comprises an annular helical, at both ends of the pile to 2000mm range stirrups encrypted area, spiral stirrup stirrup pitch and cyclic pitch of this range is not more than 45mm, and the rest of the annular spiral stirrups stirrup spacing pitch no greater than 80mm, and will make a good reinforcement cage placed on the lower mold;

[0032] (2) The structure of the reinforcement cage using circular end plate 3, and the reinforcement plate at a position corresponding to the end opening has the same number of reinforcement counterbore 3-1, the blind hole is located inside the end plate; wear reinforcement after 3-1 into the counterbore with the end plates welded;

[0033] (3) cement, sand, stone, mineral admixtures and superplasticizer according to a bulk density, water-cement ratio of 0.25~0.35, sand ratio 0.25~0.38, the total gelling materials with 0.16~0.21 ratio, mineral additives content controlled within 30% of the total cementitious material, depending on the superplasticizer water reducing rate, the dosage of 0.6~3.0% each metered raw materials, after mixing, fabric, molded together concrete pipe pile;

[0034] (4) at one end of the pipe pile strands tensioning machine employed, in accordance with the production process prestressing reinforcement, so that the effective compressive prestress in concrete 3.0~5.0N/mm2.;

[0035] After (5) tensioning step, with a pipe placed on the mold Φ300-Φ600/15Μ frequency centrifuge group roller, centrifugal molding, into low-speed-high speed-high speed four stages: low 200~300r/min running 2~3min; speed 500~600r/min operation 1~2min; high-speed 800~1000r/min running 1.5~3min; high speed 1100~1400r/min running 5~10min;

[0036] (6) lifting the mold with concrete pipe pile to steam curing tank, allowed to stand 2~4h, then through the steam curing, the pool was warmed to 80~85°C, held April to a temperature at 80~85°C 6h, 3h and then cooled to room temperature; secondary autoclave curing in the autoclave was heated to 175~185°C in 3~4h, raised to 0.8~1.2MPa, April to pressure after maintaining the temperature. he, 2~3 pool the pressure was reduced to atmospheric pressure in the autoclave, the autoclave when the temperature is below 100°C, open pile transport vessel;

[0037] (7) with the pile lifting the mold to release zone, stripping, passing routine testing, to yard crane.

[0038] Example II:

[0039] 1, 3 and 4, differs from the manufacturing process and the manufacturing process of a centrifugal concrete pipe pile side of the pile and that the selection of the end plate of the mold, the same as with other processes Pile, which is not repeat.

[0040] The production process of the invention compared with similar products pile to Φ400 (95)-080 prestressed high strength concrete pipe (PHC) do comparison.

[0041] PHC 400A 95-C80 PHC pipe piles, reinforcement using 7Φ9.0 prestressing steel bars, steel bars prestressed tensile strength of not less than 1420 MPa, non-proportional extension strength is not less than 1280MPa. Effective pre-stress concrete pipe pile 4.30MPa, mechanical properties mainly as follows:

[0042] The design value of bending capacity of pile seriously: [Μ] =64KN·m

[0043] Shear seriously pile bearing capacity design values: [V] =146KN

[0044] The sustained pile bearing capacity pull design values: [N] =38IKN

[0045] AXIAL PRESSURE pile design values: [R] =2286KN

[0046] The present invention produced with the specifications Pile, S Jie Φ 400 (95) -C80, an outer diameter of 400mm, thickness 95mm, reinforcement using 9Φ14.0, rolled ribbed bar HRB400, tensile strength is not low to 570MPa. Effective pre-stress concrete pipe pile 4.37MPa, mechanical properties mainly as follows:

[0047] The design value of bending capacity of pile seriously: [Μ] =72KN·m

[0048] Design Shear Capacity value seriously Pile: [V] =146.8KN

[0049] The sustained pull pile bearing capacity design values: [N] =423.8KN

[0050] AXIAL PRESSURE pile design values: [R] =2286KN

[0051] contrast can be found, the present invention is produced Φ400 (95) -080 Piles and PHC 400 A95-C80 PHC pipe piles under the same conditions effective prestress concrete, without a substantial increase in production costs premise (at current materials, energy, labor, and management expenses, increased by about 20%), the design value of bending capacity of the pile can seriously increase 12.5%, the design values of tension by pulling the bearing capacity can be increased 11.2%. Accordingly, it is possible to effectively reduce or avoid brittle fracture problems of the pile, the same conditions, improved horizontal bearing capacity of the pile.

[0052] PHC 400A 95-C80 prestressed reinforcement ratio at 0.49%, which can satisfy the above basic mechanical properties; and the use of the present invention is produced Φ400 (95)-080 pipe pile, to achieve the above basic mechanical properties in when the index, prestressing steel reinforcement ratio at 1.52%.