VFD in concrete pile production line

I. Overview

As an electronic speed regulating device with very high automation degree, it has wide speed regulating scope, stable speed and high precision.

Furthermore, it can realize automatic control and have convenient operation. concrete pilesIt has become an incomparable product of other speed regulating devices. Therefore, it is widely used in various industries. As to the concrete pile production line, before employing the VFD, it generally adopts the electromagnetism motor or DC motor for speed regulating. Since the electromagnetism motor has no high speed regulating precision and limited speed regulating scope, some requirements on high speed can't be realized. In addition, in the concrete pile manufacturing process, different speeds and times are required. The speed can only be regulated manually and the operating time of different speeds will be calculated with the stopwatch. Like this, the labor intensity of the workers is extremely high and the manufacturing efficiency is rather low. If the operating workers can't concentrate on the manufacturing, it might scrap the tubular pipes and bring great loss to the factory.

In the entire manufacturing process of the concrete pile, molding on the centrifuge is the most vital step. This process includes: Cloth distribution, second level transition, compacting three stages. Different stages have different requirements to the revolving speed and time of the tubular pipe. In addition, the tubular pipes of different wall thickness and length will have different requirements to the revolving speed and time of the three stages. This requires the VFD to be able to regulate the working stage of the motor according to the different types of concrete piles. It will operate different speed and time at different stages to ensure the product quality of the concrete pile. Aimed at the characteristics of the technological requirements of the concrete pile, our company develops the exclusive VFD suitable for various concrete piles. It has big starting torque. According to the different sizes, raw materials and technological requirements of the manufactured concrete pile, five different operating modes of the concrete pile have been set, with each mode can be set four different operating frequency and operating time randomly, thus improving the manufacturing efficiency greatly. In addition, it has a good energy saving effect and reduces the labor intensity of the operators.

II. Working principle

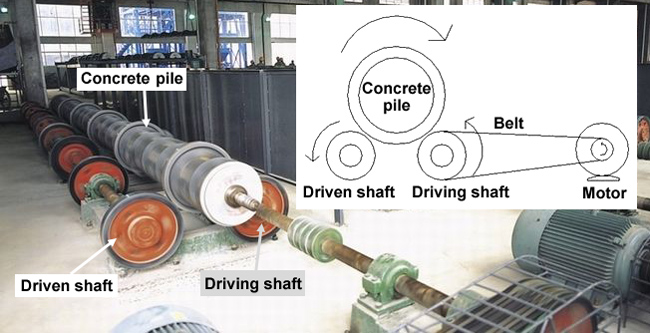

The concrete pile is set at the included angle of the driving shaft and driven shaft. The electrical motor will drive the driving shaft to revolve. Then the concrete pile will revolve according to a certain speed and time because of the friction of the driving shaft.

III. Some technical parameters of the frequency conversion concrete pile production line:

Five working modes can be setting in advance. Each mode can be set with four sections of different speed and operating time. The operating mode can be selected as the different concrete pile size and the raw material.

The starting and stop of the system adopts two-wire system to control. It can be realized with the button.

Three-section V/F curve can be set manually, so that the concrete pile will have stable and powerful starting in low frequency. It ensures the continuity of the system operation.

Break-point memory function: if the system has to be stopped in halfway because of a certain reason, the VFD can continue to work as the stage frequency stopped at the last time when it is restarted. There is no need for the customers to make further regulations.

IV. Set the basic parameters of VFD in concrete pile production line

| Function Code | Name | Set Value | Remark |

| P0.03 | Operating command channel | 1 | Terminal operation |

| P0.04 | Set the operating direction | 10 | Reverse revolving is not allowed |

| P0.09 | Torque rising | 3.0 | Set the torque properly |

| P0.17 | Acceleration time 1 | 15 | Set According to the field condition |

| P0.18 | Deceleration time 1 | 50 | |

| P0.22 | V/F curve setting | 4 | Multistage V/F curve |

| P0.23 | V/F frequency value F3 | 41 | Set according to the field condition |

| P0.24 | Voltage value v3 | 100 | |

| P0.25 | Frequency value F2 | 18 | |

| P0.26 | Voltage value v2 | 36 | |

| P0.27 | Frequency value F1 | 5 | |

| P0.28 | Voltage value v1 | 12 | |

| P2.05 | Halt mode | 1 | Freely halt |

| P4.08 | Selection of the starting and stopping operation mode | 0 | FWD start, REV stop |

| P7.00 | Selection of the operating modeof the concrete pile PLC | 0 | The stage and frequency in reserving and power off instant |

| Continue to operate at the frequency of breaking off | |||

| Stop after single cycle | |||

| P7.01 | Mode setting of the concrete pile production line | 1 | Mode 1 |

| P7.02 | The first operating frequency ofmode 1 | 18 | Set according to the field condition |

| P7.03 | The first operating time of mode 1 | 90 | |

| P7.04 | The second operating frequency of mode 1 | 28 | |

| P7.05 | The second operating time of mode 1 | 60 | |

| P7.06 | The third operating frequency of mode 1 | 35 | |

| P7.07 | The third operating time of mode 1 | 60 | |

| P7.08 | The fourth operating frequencyof mode 1 | 41 | |

| P7.09 | The fourth operating time of mode 1 | 420 |

Note: only all parameters of mode 1 have been set from P7.02-P7.09. The customers can set the other four modes through parameters P7.10-P7.41 according to the practical requirements.

V. Matters needing attention

Keep the working environment to be dry and ventilated, prevent the mud thrown by the concrete pile to splash into the cabinet of the VFD.

Set the torque properly as the practical condition, so as to reach the best effect.

The system must be grounded with reliability, so as to prevent from the operators to have electric shock hazard.